Compared with terrazzo and emery, the cement concrete floor is much monotonous, and the hardness and strength are not as good as the two, and it is easy to be damaged by aging.

The service life of the cement concrete floor is relatively short. After long-term use, it gradually enters the aging stage. Under the effects of aging, weathering, and external forces, it is a normal phenomenon for the cement concrete floor to get ash, especially the cement floor with poor engineering quality. , The aging rate is fast, and the degree of damage is more serious. In addition to dusting, hollowing, cracks, holes, breakage, etc. will also occur. Using a concrete floor grinder does this kind of project. Causes of dust on the cement concrete floor:

1. Cement quality problem: The cement is counterfeit, or is expired and wet.

2. Too little cement consumption: the construction party cut corners to save costs.

3. Water-cement ratio: if the water-cement ratio is too high, concrete bleeding will occur.

4. Construction process: error in the process, improper process, and problems during maintenance.

These factors will affect the strength of the cement concrete floor. The strength is insufficient, and the aging will be accelerated under the action of external forces (such as friction, forklift back and forth, carrying heavy objects, etc.), and the ground is easily damaged.

5. Ground aging and weathering: The service life of concrete is relatively short. After entering the aging period, the cement concrete ground is easily damaged due to its own internal reasons.

Pay attention to these problems in the construction process of cement concrete floors to ensure the quality of the ground. In addition, when the cement concrete floor is dusty, the platinum crystal floor system-curing construction process is used to deal with it in time. By chemically hardening the ground and mechanical grinding and polishing, a cement with high hardness, high density, and high brightness can be created. Concrete curing ground.

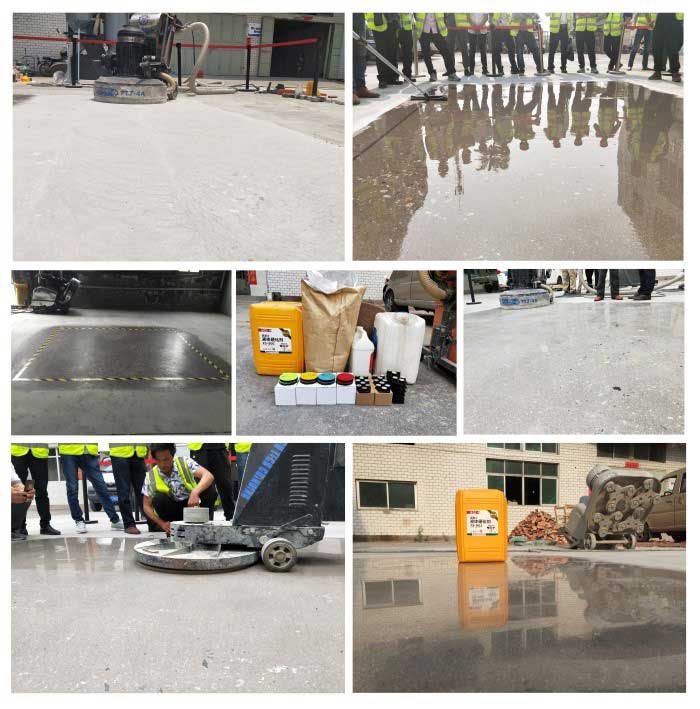

Treatment method: concrete curing construction process

Specific steps:

1. Base surface cleaning

Clear the garbage, check the condition of the terrazzo floor, and remove hard materials such as expansion screws.

2. Rough grinding and leveling

Driven floor grinder with metal grinding disc 30#, 60#, 150#, resin grinding disc -50#, 100# dry grinding treatment, until the surface of the terrazzo is even and smooth, and the ground dust is cleaned.

3. Hardener penetration

After cleaning the ground, use penetrating liquid hardener FS-801 to spray evenly on the ground. Keep the ground moist for 1 hour and keep it healthy for more than 12 hours.

4. Fine grinding

Driven concrete floor grinder cooperates with resin grinding disc 200#, 400# to finely grind and clean the ground dust.

5. Polishing

Driven concrete floor grinder and high-speed polishing machine cooperate with resin polishing pad 800# and the high polishing pad 800# for polishing.

Use a high polishing machine and high polishing pad 1500# with the protective agent for ground polishing.

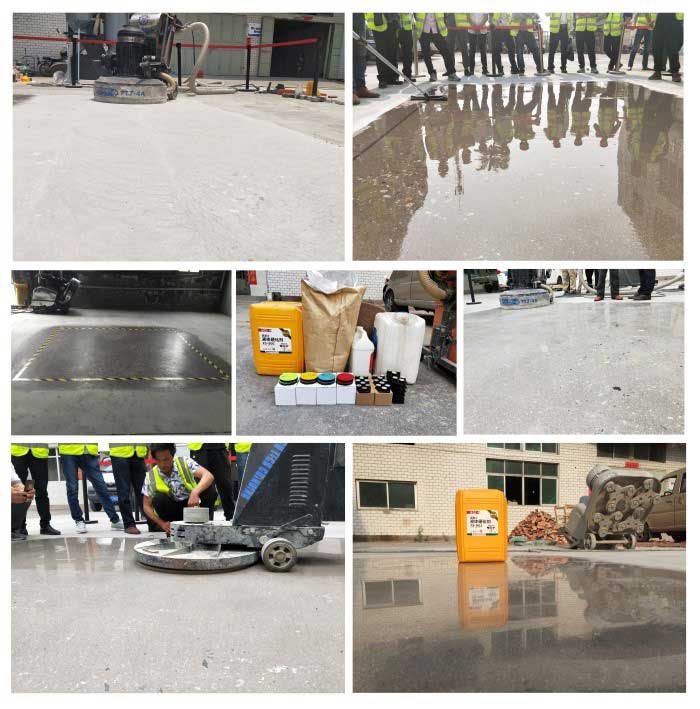

Concrete floor after treatment:

1. Green and environmental protection: The floor system uses certified environmental protection materials, which are safer and more assured.

2. No sand or ash: After the ground is processed by the floor system, the hardness, density, and brightness are significantly improved, and the ground is more wear-resistant and can be used for longer.

3. Wear-resistant and compressive: After the ground is processed by the floor system, it can bear the rolling and friction of forklifts and heavy objects back and forth.

4. Anti-fouling and dirt-resistance: After the ground is treated by the floor system, it can effectively delay the penetration of water, oil, acid, and alkali, and the ground is more beautiful and clean, helping to enhance the image and strength of the factory.

5. Easy to clean and low maintenance cost: After the ground is treated by the floor system, the ground is easy to clean. After several years of use, if the gloss decreases, it can be restored to the original after polishing again. The maintenance using Maxkpa concrete floor grinder is simple and the cost is greatly reduced.

Publication Date: 8 February, 2021

Category:

Concrete Floor Grinder